IoT Based Environment Monitoring System

Project name: IoT Based Environment Monitoring System

For online monitoring : https://io.adafruit.com/

Download full project here : Front Page Link

Project body Link

On

“IoT Based Environment Monitoring System”

Submitted

By

Sohanoor Rahman

ID:

Mazedur Rahman

ID:

Md. Eazajul

Islam

ID:

Md. Samiul Islam

ID

:

Md.

Al Mamun Mia

ID:

Supervised by

Maksuda

Khatun

Sr.

Lecturer

Department of Computer Science and Engineering

A

project submitted in partial fulfillment of the requirements for the degree of

Bachelor of Science in Computer Science and Engineering.

Department

of Computer Science and Engineering

European

University of Bangladesh

2/4, Gabtoli, Mirpur,

Dhaka-1216

March 2022

CANDIDATES’

DECLARATION

This is

to certify that the work presented in this thesis/project, titled, “IoT Based Environment Monitoring System”, is the outcome of the investigation and research carried out by us under

the supervision of Maksuda Khatun.

It is

also declared that neither this thesis/project nor any part thereof has been

submitted anywhere else for the award of any degree, diploma or other

qualifications.

|

|

Signature

----------------------- |

|

|

Signature

-------------------------- |

|

|

-------------------- |

|

|

------------------------ |

|

|

Signature

------------------------ |

CERTIFICATE OF APPROVAL

This

thesis/project titled, “IoT Based Environment

Monitoring System”,

submitted by the group as mentioned in the candidates’ declaration page has

been accepted as satisfactory in partial fulfillment of the requirements for

the degree B.Sc. in Computer Science and Engineering in March 2022.

Signature

of Supervisor:

----------------------------------------

Maksuda

Khatun

Sr. Lecturer

Department

of Computer Science and Engineering

European

University of Bangladesh, Dhaka, Bangladesh.

Signature

of Chairperson:

---------------------------------------------

Chairperson

Name

Associate

Professor and Chairperson

Department

of Computer Science and Engineering

European

University of Bangladesh, Dhaka, Bangladesh

ACKNOWLEDGEMENT

We

would like to express our greatest gratitude to the people who helped and

supported us throughout this work. First and foremost, we would like to thank

our honorable supervisor, Maksuda Khatun,

Sr. Lecturer, Department of CSE, for giving us enormous support, advices and

valued guidance concerning this thesis.

We

are grateful to Md. Obaidur Rahman, Honorable Associate Professor and

Chairman, Department of CSE, Faculty of Engineering, European University of

Bangladesh (EUB) for his comments, encouragement and support.

We

are grateful to our respected coordinator

Maksuda Khatun, Lecturer, Department of CSE, Faculty of Engineering,

European University of Bangladesh (EUB) for kindly agreeing to examine my

thesis.

Next,

we would like to thank our family and friends for their valuable support to

complete this thesis.

Finally,

we would like to express my/our heartiest gratefulness to Almighty Allah for

His heavenly blessings. Without his blessings it would not possible to complete

my/our work successfully.

Thank

you all.

Authors

Sohanoor Rahman

Mazedur Rahman

Md. Eazajul Islam

Md. Samiul Islam

Md. Al Mamun Mia

ABBREVIATIONS

|

AC |

Alternating

Current |

|

DC |

Direct Current |

|

Wi-Fi |

Wireless

Technology |

|

MCU |

Microcontroller

Unit |

|

USB |

External Serial

Bus Interface |

|

PCB |

Printed Circuit

Board |

|

IC |

Integrated

Circuit |

|

GND |

Ground |

|

SIM |

Subscriber

Identification Module |

|

Tx |

Transmitter |

|

Rx |

Receiver |

|

Nc |

Normally Closed |

|

No |

Normally Open |

Table of Contents

|

SL No. |

Chapter

Name |

Page

No. |

|

01 |

Project Details Front Page |

I |

|

02 |

Candidates

Declaration |

II |

|

03 |

Certificate of Approval |

III |

|

04 |

Acknowledgement |

IV |

|

05 |

Abbreviations |

V |

|

06 |

Abstract |

X |

|

|

|

|

|

|

Chapter

1: Introduction |

|

|

1.1 |

Background |

1 |

|

1.2 |

Objectives |

1 |

|

1.2 |

Methodology |

2 |

|

|

|

|

|

|

Chapter

2: Background |

|

|

2.1 |

Literature

Review |

3-4 |

|

|

|

|

|

|

Chapter

3: Related Works |

|

|

3.1 |

System Model |

5 |

|

3.2 |

Block Diagram |

5 |

|

3.3 |

Circuit

Diagram |

6 |

|

3.4 |

Working Principle |

6-7 |

|

3.5 |

The

Project Prototype |

7 |

|

3.6 |

Cost Analysis |

8 |

|

|

|

|

|

|

Chapter

4: Hardware and Software |

|

|

4.1 |

Required Instrument |

10 |

|

4.2 |

Node

MCU |

09-11 |

|

4.3 |

Switch Mood Power Supply |

11-16 |

|

4.4 |

The

Smoothing Capacitor |

16-18 |

|

4.5 |

5V Regulator IC |

18-19 |

|

4.6 |

Temperature

Sensor |

19-20 |

|

4.7 |

LCD Display |

20-21 |

|

4.8 |

Gas

Sensor |

21-24 |

|

4.9 |

Resistor |

24-25 |

|

4.10 |

Buzzer |

25-26 |

|

4.11 |

Arduino IDE |

27-28 |

|

4.12 |

Proteus Software |

29 |

|

4.13 |

Microcontroller

Code |

30-35 |

|

|

|

|

|

|

Chapter

5: Conclusion |

|

|

5.1 |

Advantages

|

36 |

|

5.2 |

Disadvantages |

36 |

|

5.3 |

Application |

36 |

|

5.4 |

Future Scope of Work |

37 |

|

5.5 |

Conclusion |

37 |

|

|

References |

38-39 |

List of Figures

|

Figure No. |

Name |

Page

No. |

|

3.1 |

Block Diagram |

5 |

|

3.2 |

Circuit

Diagram |

6 |

|

3.3 |

The Complete Prototype of the Project |

7 |

|

4.1 |

Node

MCU |

11 |

|

4.2 |

SMPS |

12 |

|

4.3 |

Basic

Working Concept of an SMPS |

13 |

|

4.4 |

SMPS Diagram |

15 |

|

4.5 |

DC

Power Supply Way |

16 |

|

4.6 |

Capacitor |

16 |

|

4.7 |

The

Smoothing Capacitor |

18 |

|

4.8 |

5V Regulator IC |

19 |

|

4.9 |

Temperature

sensor |

20 |

|

4.10 |

LCD Display |

21 |

|

4.11 |

Gas

sensor |

22 |

|

4.12 |

Resistor |

25 |

|

4.13 |

Buzzer |

26 |

|

4.14 |

Arduino Software Interface IDE |

28 |

|

4.15 |

Proteus

Software Interface |

29 |

List of Tables

|

SL

No. |

Name |

Page No. |

|

3.1 |

Cost of Components with Price |

8 |

ABSTRACT

Today

environment monitoring becomes important for humans to ensure a safe and

wealthy life. Monitoring requirements are extremely different depending on the

environment, leading to specially appointed usage that needs adaptability. At

first circuit is designed by using hardware. In this project we are going to

build a Weather Station & data base with IoT Technology. Building a IoT

Weather Station & Database is a great learning experience. When we

completed this project, we will have a better understanding of how sensors

work, and how powerful the Arduino platform can be.

With this project as a base and

the experience gained, we will be able to easily build more complex projects in

the future. A Weather station is a device that collects data related to the weather

and environment using many different sensors & it stores a database with

IoT Platform. We used smoke & temperature sensor which collect the weather

smoke, temperature & humidity & send this data IoT Platform Using Node

MCU via internet. after storage this data next time collected this data for

data analyzing.

In

comparison to other closely related systems, the proposed system is a low-cost

one, accurate and user friendly. It is also cloud-based and has easy monitoring

and data visualization modules. The system has been evaluated in different

stages. After testing all the functions in different conditions, it shows a

high degree of accuracy and reliability.

Introduction

1.1

Background

Weather and climate are among the foremost factors

which determine how a society develops in geographical region. Weather usually

describes the particular event or condition for the short period of time such

as hours or days whereas climate refers to the behavior of the atmosphere to a

place over many years. On the other hand, weather includes current atmospheric

conditions such as the temperature, precipitation, humidity and the wind while

climate describes the general weather conditions of a certain area over a long

period of time. Weather data are important in our daily life. The data

collected such as rainfall and temperature can be used to serve as a

precautionary measure to against natural calamity or disaster such as flood and

drought. Besides that, it is important for others to plan the works. For

example, in the construction industry, the weather data is important for a

project manager to plan their schedule so that the project will complete on

time. The weather data collected, or a long period are used to predict the

climate change in future trends. The weather data collected for the past decade

can be used to analysis in order to identify the pattern of climate change.

Weather station is one of the devices to collect the weather data. The weather

data such as precipitation, humidity, temperature, and wind speed can be

collected by using this device. The usage of weather station is increasing

popularity among the nation.

1.2 Objectives

We have some specific

objectives for this project, and they are pointed below:

·

Design

& Construction of a IoT Based Environment

Monitoring System.

·

Implementation

of automatic temperature monitoring system.

·

Implement

Automatic Smoke Monitoring System.

1.3 Methodology

Our methodology for the project:

Ø Design and construction of a IoT Based Environment Monitoring System block diagram to know which components need to construct it.

Ø Collecting the all components and programming

for the controller to controlled the system.

Ø Setting all components in a PCB board &

soldering. Then assembling the whole block in a board and finally run the

system & checking.

Background

2.1 Literature Review

P.Raja,

Swapnil sBagwari et alia (2018) presented a MASS( military assistance and

security system) that uses several kinds of the sensor to notice the soldier

featuring their place, wellness as well as wellness troubles, environments,

delivering information to the base station, etc. being a wearable device it

tracks the rhythm fee aside from delivering the respective documents to the

base station as well as by utilizing GPS element the spot can conveniently

additionally be kept an eye on using armed forces base station. Thinking about

that it is wearable instalment will undoubtedly be cost-effective and are

heading to add a massive bundle weight for soldier Minals.

Ghute,

KanchanP.Kamble, MridulKorde et al (2018) discussed an army surveillance

automated system that features an atypical system, which is going to certain ly

inspect the setting in various unsafe health and wellness conditions along with

supply on the internet video reviews. Gyro sensor has been used to relocate

robotic in uneven locations, metallic detection for landmines [15]. It utilizes

a Bluetooth link for cordless communication via a mobile application that makes

it very marginal. AdityaPrakash, Raheewalambe et al (2018) explained regarding

uncomplicated armed forces monitoring robot along with the controls for transferring

face, back, right, left behind as well as additionally quit are being received

coming from the remote driver and additionally accordingly the input is

supplied to the Raspberry private investigator 3 which makes the robot

arrangement answer based on the guidelines provided. The Kinect sensor

functionalities like a video camera along with additional functionality of

magnitude dimension i.e. it reveals the range of object coming from on its own

by personifying the product like grayscale worths varying coming from 0 to 255

where 0 amounts to dark which indicates the object is closed as well as

likewise 255 total up to white tinted which indicates things a greater

distance.

Siva

karteekbolisetti, Mohammad pathway, Mohamed Abdel-magid et alia (2017) planned

Radio Frequency picking up situated aim at the sensor which is assumed to

supply a power reliable solution to the complication of intending for detection

under the noticing issues. The sensor nodes are required to function in serious

noticing settings in the visibility of clutter and also meddling indicators.

Making use of a simply reduced complexity target detector at the private sensor

nodes may be taken a look at where the sensor nodes can easily assisting make a

preparatory option before transferring the info to the command location [11].

This

decreases the uniformity of information swap in between the sensor nodes as

well as likewise the management resource thus rearing the life-time of the

IoT.70% security has been accomplished. Ghanem Osman ElhajAbdalla, T.

Veeramanikandasamyet alia (2017) carried out a Spy Robotic for A Monitoring

System using the Internet Technique of Raspberry Pi a Raspbian operating system

located spy robot system with remote monitoring as well as management formula

using the Internet of Things (IoT). The information relating to the detection

of staying objects by PIR sensor is delivered to the clients using the internet

server in addition to private detective video camera catch the relocating

traits which are provided inside the web site concurrently [14].

Majdghareeb,

Alibazzi, mohamadraad, shamihabdulnabi et al (2017) supplied Wireless Robo

private eye for landmine detection as an affordable automated mine detector

that is heading to modify the current private sensors in the goal of finding

and also taking out mines in an assumed area of land. This sensor will

wirelessly call a server to deliver the site of discovered mines or even

metallic and likewise took hold of the image of the property where it is

located. As a result of the simple fact that the sensor is raspberry private

detective based our experts can make it as iot based for additional

interaction.

Widodo

Budiharto et al (2014) developed a Tracked Robotic alongside Remote Control for

Surveillance, the efficiency of the robotic dwells in terms of the closeness

and also the capability to supply on the web video streaming coming from the

outcome raspberry private eye and 2.4 GHz online video transmitter. Speculative

results with a variety of span current that the best optimal distance for

broadcasting the purchases not much more than twenty gauges. The sensor system

is truly affordable thinking that it simply makes use of a 1-period sensor. The

ordinary speed raspberry pi to provide a video clip streaming is 33 fps that

ample security. The main weak point of sort of ultrasound examination sensor is

the disturbance in between different sensors and the limited ability to

pinpoint the problem.

Related Workss

3.1

System Model

In this

system here we use a microcontroller for controlling this whole system. Also

use here SMPS, Voltage Regulator, Temperature sensor, Gas Sensor and LCD

Display. All the equipment’s are work together when power will input of this

system.

3.2 Block Diagram

In this chapter

fully cover with discuss design and fabrication of this project. Here we will

discuss about developed block diagram and briefly describe about the circuit

description and learn about working principle. Total project flow chart is also

available in this chapter.

Figure 3.1: Block Diagram

3.3 Circuit Diagram

Figure

3.2: Circuit Diagram

3.4 Working Principle

Digital Weather

Station Data Storage project consists of parameters monitoring, parameter

Storage. We have used Node MCU as a main component of the project. Two sensors

are included this project such as temperature sensor, Gas sensor module for

collected the various data of weather. This project consists of two basic

parts. First is Data Monitoring & other is data storage via internet. A

display Unit will show the value of parameters. This will help for the person

to know the values, for this purpose we are going to use various Sensors. This

system is useful because many times It’s difficult to measure the parameter

Values manually and this module is more accurate than the domestic system. Here

we used two sensors one of gas sensing and another one temperature sensor this

sensor is input device of this project. We used Node MCU as main brain of this

project. A LCD display we used as a output device which can displaying all

information of this project. Sensor sensing the gas & temperature from

surrounding environment then send this signal Node MCU. Node MCU calculate

& analyzed this signal then displays it on the screen.

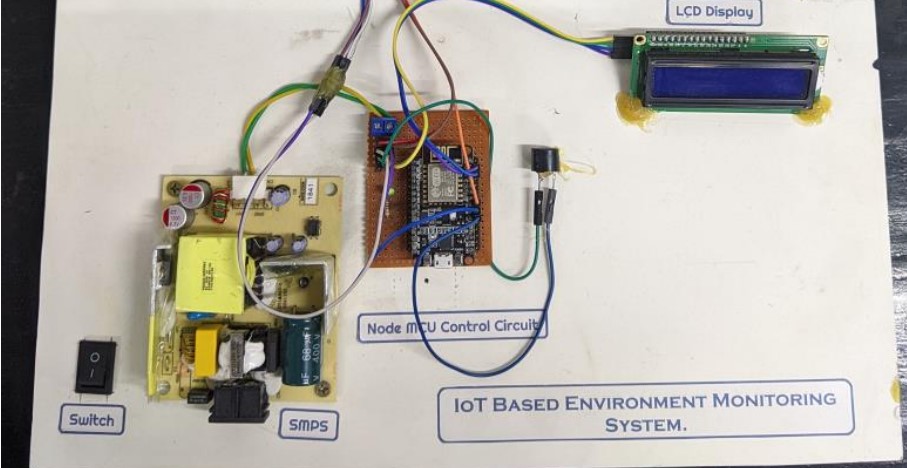

3.5 The Project Prototype

The complete prototype

of our project is shown below:

Figure

3.3: The Complete Prototype of the Project

3.6 Cost Analysis

In

the below table we have summarized our project expenditure.

Table

3.1: Cost of Components with Price

|

Sl. no |

Particulars |

Specification |

Qty. |

Unit Price (Taka) |

Total Price (Taka) |

|

1 |

Node MCU |

ESP8266 |

1 |

580 |

580 |

|

2 |

Temperature Sensor |

DHT 11 |

1 |

220 |

220 |

|

3 |

SMPS |

5V, 5Amp |

1 |

450 |

450 |

|

4 |

Gas Sensor

|

MQ2 |

1 |

180 |

180 |

|

5 |

LCD

Display |

16*2 |

1 |

420 |

420 |

|

6 |

Active

Buzzer |

5v |

1 |

20 |

50 |

|

7 |

Others |

|

1 |

1250 |

1500 |

|

Total |

3400/= |

||||

Hardware and Software

4.1 Required Instrument

1.

Node MCU

2.

LCD Display

3.

Temperature Sensor

4.

Gas Sensor

5.

SMPS

6.

Voltage Regulator

7.

Capacitor

8.

Resistor

9.

Buzzer

4.2 Node MCU

Node

MCU is an open-source firmware for which open-source prototyping board designs

are available. The name "Node MCU" combines "node" and

"MCU" (micro-controller unit). The term "Node MCU" strictly

speaking refers to the firmware rather than the associated development kits.

Both the firmware and prototyping board designs are open source.

The

firmware uses the Lua scripting language. The firmware is based on the eLua

project, and built on the Espressif Non-OS SDK for ESP8266. It uses many open

source projects, such as lua-cjson and SPIFFS. Due to resource constraints,

users need to select the modules relevant for their project and build a

firmware tailored to their needs. Support for the 32-bit ESP32 has also been

implemented.

The

prototyping hardware typically used is a circuit board functioning as a dual

in-line package (DIP) which integrates a USB controller with a smaller

surface-mounted board containing the MCU and antenna. The choice of the DIP

format allows for easy prototyping on breadboards. The design was initially was

based on the ESP-12 module of the ESP8266, which is a Wi-Fi SoC integrated with

a Tensilica Xtensa LX106 core, widely used in IoT applications.

Features:

Wi-Fi

Module – ESP-12E module similar to ESP-12 module but with 6 extra GPIOs. USB –

micro USB port for power, programming and debugging Headers – 2x 2.54mm 15-pin

header with access to GPIOs, SPI, UART, ADC, and power pins Misc. – Reset and

Flash buttons Power – 5V via micro USB port Dimensions – 49 x 24.5 x 13mm Node

MCU was created shortly after the ESP8266 came out. On December 30, 2013,

Espressif Systems began production of the ESP8266. The ESP8266 is a Wi-Fi SoC

integrated with a Tensilica Xtensa LX106 core, widely used in IoT applications

(see related projects). Node MCU started on 13 Oct 2014, when Hong committed

the first file of NodeMCU-firmware to GitHub. Two months later, the project

expanded to include an open-hardware platform when developer Huang R committed

the gerber file of an ESP8266 board, named devkit v0.9. Later that month, Tuan

PM ported MQTT client library from Contac to the ESP8266 SoC platform, and

committed to Node MCU project, then Node MCU was able to support the MQTT IoT

protocol, using Lua to access the MQTT broker. Another important update was

made on 30 Jan 2015, when Devsaurus ported the u8glib to Node MCU project,

enabling Node MCU to easily drive LCD, Screen, OLED, even VGA displays. In

summer 2015 the creators abandoned the firmware project and a group of

independent contributors took over. By summer 2016 the Node MCU included more

than 40 different modules. Due to resource constraints users need to select the

modules relevant for their project and build a firmware tailored to their

needs.

ESP8266 Arduino Core:

As

Arduino.cc began developing new MCU boards based on non-AVR processors like the

ARM/SAM MCU and used in the Arduino Due, they needed to modify the Arduino IDE

so that it would be relatively easy to change the IDE to support alternate

toolchains to allow Arduino C/C++ to be compiled for these new processors. They

did this with the introduction of the Board Manager and the SAM Core. A

"core" is the collection of software components required by the Board

Manager and the Arduino IDE to compile an Arduino C/C++ source file for the

target MCU's machine language. Some ESP8266 enthusiasts developed an Arduino

core for the ESP8266 WiFi SoC, popularly called the "ESP8266 Core for the

Arduino IDE". This has become a leading software development platform for

the various ESP8266-based modules and development boards, including Node MCUs.

Figure 4.1: Node MCU

Applications of NODEMCU

The

Prototyping of IoT devices

It

has Low power battery operated applications

Used

in Network projects

The

Projects requiring multiple I/O interfaces with Wi-Fi and Bluetooth

functionalities

4.3 Switch Mode Power Supply

(SMPS):

A switched-mode power supply (switching-mode power supply, switch-mode power supply, switched power supply, SMPS, or switcher)

is an electronic power supply that

incorporates a switching

regulator to convert

electrical power efficiently.

Like other power supplies, an SMPS transfers power from a DC or AC source

(often mains

power) to DC loads,

such as a personal

computer, while

converting voltage and current characteristics. Unlike a linear

power supply, the

pass transistor of a switching-mode supply continually switches between low-dissipation, full-on and full-off states, and spends very

little time in the high dissipation transitions, which minimizes wasted energy.

A hypothetical ideal switched-mode power supply dissipates no power. Voltage regulation is achieved by varying the ratio

of on-to-off time (also known as duty cycles). In contrast, a linear power supply regulates the

output voltage by continually dissipating power in the pass transistor. This higher power conversion efficiency is an important

advantage of a switched-mode power supply. Switched-mode power supplies may

also be substantially smaller and lighter than a linear supply due to the

smaller transformer size and weight.

|

|

|

Figure

4.2: SMPS

Switching regulators are used as

replacements for linear regulators when higher efficiency, smaller size or

lighter weight are required. They are, however, more complicated; their

switching currents can cause electrical noise problems if not carefully

suppressed, and simple designs may have a poor power factor.

Switched-mode power supplies are classified

according to the type of input and output voltages. The four major categories

are:

- AC

to DC

- DC

to DC

- DC

to AC

- AC

to AC

A basic isolated AC to DC switched-mode power

supply consists of:

- Input

rectifier and filter

- Inverter

consisting of switching devices such as MOSFETs

- Transformer

- Output

rectifier and filter

- Feedback

and control circuit

The input DC supply from a rectifier or

battery is fed to the inverter where it is turned on and off at high

frequencies of between 20 KHz and 200 KHz by the switching MOSFET or power

transistors. The high-frequency voltage pulses from the inverter are fed to the

transformer primary winding, and the secondary AC output is rectified and

smoothed to produce the required DC voltages. A feedback circuit monitors the

output voltage and instructs the control circuit to adjust the duty cycle to

maintain the output at the desired level.

Figure 4.3: Basic working concept

of an SMPS

A switching regulator does the

regulation in the SMPS. A series switching element turns the current supply to

a smoothing capacitor on and off. The voltage on the capacitor controls the

time the series element is turned. The continuous switching of the capacitor

maintains the voltage at the required level.

Design basics

AC power first passes through fuses

and a line filter. Then it is rectified by a full-wave bridge rectifier. The

rectified voltage is next applied to the power

factor correction (PFC)

pre-regulator followed by the downstream DC-DC converter(s). Most computers and

small appliances use the International Electrotechnical Commission (IEC) style input connector. As for output connectors and

pinouts, except for some industries, such as PC and compact PCI, in general,

they are not standardized and are left up to the manufacturer.

There are different circuit configurations

known as topologies, each having unique characteristics, advantages and modes

of operation, which determines how the input power is transferred to the

output.

Most of the commonly used topologies such as

flyback, push-pull, half bridge and full bridge, consist of a transformer to

provide isolation, voltage scaling, and multiple output voltages. The

non-isolated configurations do not have a transformer and the power conversion

is provided by the inductive energy transfer.

Advantages

of switched-mode power supplies:

- Higher

efficiency of 68% to 90%

- Regulated

and reliable outputs regardless of variations in input supply voltage

- Small

size and lighter

- Flexible

technology

- High

power density

Disadvantages:

- Generates

electromagnetic interference

- Complex

circuit design

- Expensive

compared to linear supplies

Switched-mode power supplies are used to

power a wide variety of equipment such as computers, sensitive electronics,

battery-operated devices and other equipment requiring high efficiency.

Linear voltage IC regulators have been

the basis of power supply designs for many years as they are very good at

supplying a continuous fixed voltage output. Linear voltage regulators are

generally much more efficient and easier to use than equivalent voltage

regulator circuits made from discrete components such a zener diode and a

resistor, or transistors and even op-amps.

Figure

4.4: SMPS Diagram

The most popular linear and fixed

output voltage regulator types are by far the 78… positive output voltage

series, and the 79… negative output voltage series. These two types of

complementary voltage regulators produce a precise and stable voltage output

ranging from about 5 volts up to about 24 volts for use in many electronic

circuits. There is a wide range of these three-terminal fixed voltage

regulators available each with its own built-in voltage regulation and current

limiting circuits. This allows us to create a whole host of different power

supply rails and outputs, either single or dual supply, suitable for most

electronic circuits and applications. There are even variable voltage linear

regulators available as well providing an output voltage which is continually

variable from just above zero to a few volts below its maximum voltage output.

Most d.c. power supplies comprise of a

large and heavy step-down mains transformer, diode rectification, either

full-wave or half-wave, a filter circuit to remove any ripple content from the

rectified d.c. producing a suitably smooth d.c. voltage, and some form of

voltage regulator or stabiliser circuit, either linear or switching to ensure

the correct regulation of the power supplies output voltage under varying load

conditions. Then a typical d.c. power supply would look something like this:

Typical DC Power Supply

Figure

4.5: DC Power supply way

These typical power supply designs

contain a large mains transformer (which also provides isolation between the

input and output) and a dissipative series regulator circuit. The regulator

circuit could consist of a single zener diode or a three-terminal linear series

regulator to produce the required output voltage. The advantage of a linear

regulator is that the power supply circuit only needs an input capacitor,

output capacitor and some feedback resistors to set the output voltage.

4.4 The Smoothing Capacitor

When there is a potential

difference across the conductors (e.g., when a capacitor is attached across a

battery), an electric field develops across the dielectric, causing positive

charge (+Q) to collect on one plate and negative charge (-Q) to collect on the

other plate. If a battery has been attached to a capacitor for a sufficient

amount of time, no current can flow through the capacitor. However, if an

accelerating or alternating voltage is applied across the leads of the

capacitor, a displacement current can flow.

Figure 4.6: Capacitor

An ideal capacitor is characterized by a single constant value for its

capacitance. Capacitance is expressed as the ratio of the electric charge (Q)

on each conductor to the potential Difference (V). The SI unit of capacitance

is the farad (F), which is equal to one coulomb per volt (1 C/V). Typical

capacitance values range from about 1 pF (10−12 F) to about 1 mF (10−3 F). The

capacitance is greater when there is a narrower separation between conductors

and when the conductors have a larger surface area.

In practice, the dielectric between the plates passes a small amount of

leakage current and also has an electric field strength limit, known as the

breakdown voltage. The conductors and leads introduce an undesired inductance

and resistance. Capacitors are widely used in electronic circuits for blocking

direct current while allowing alternating current to pass. In analog filter

networks, they smooth the output of power supplies. In resonant circuits they

tune radios to particular frequencies. In electric power transmission systems,

they stabilize voltage and power flow.

The full-wave bridge rectifier, however, gives us a greater mean DC value

(0.637 V max) with less superimposed ripple while the output waveform is twice

that of the frequency of the input supply frequency. We can improve the average

DC output of the rectifier while at the same time reducing the AC variation of

the rectified output by using smoothing capacitors to filter the output

waveform. Smoothing or reservoir capacitors connected in parallel with the load

across the output of the full wave bridge rectifier circuit increases the

average DC output level even higher as the capacitor acts like a storage device

as shown below. Too low a capacitance value and the capacitor has little effect

on the output waveform. But if the smoothing capacitor is sufficiently large

enough (parallel capacitors can be used) and the load current is not too large,

the output voltage will be almost as smooth as pure DC.

Figure 4.7: The Smoothing Capacitor with Full Bridge Rectifier

4.5 5V

Regulator IC

Voltage sources in a circuit may have fluctuations

resulting in not providing fixed voltage outputs. A voltage regulator IC

maintains the output voltage at a constant value. 7805 IC, a member of 78xx

series of fixed linear voltage regulators used to maintain such fluctuations,

is a popular voltage regulator integrated circuit (IC). The xx in 78xx

indicates the output voltage it provides. 7805 IC provides +5 volts regulated

power supply with provisions to add a heat sink.

7805 IC Rating:

·

Input voltage range 7V- 35V

·

Current rating Ic = 1A

·

Output voltage range V. Max=5.2V ,V. Min=4.8V

Figure 4.8: 5V

Regulator IC

Application areas

for 7805 IC

·

Fixed-Output Regulator

·

Positive voltage Regulator

in Negative voltage Configuration

·

Adjustable Output

Regulator

·

Current Regulator

·

Adjustable DC Voltage

Regulator

·

Regulated Dual-Supply

·

Output

Polarity-Reversal-Protection Circuit

·

Reverse bias projection

Circuit

4.6 Temperature

Sensor

The DHT11 is a basic, ultra-low-cost

digital temperature and humidity sensor. It uses a capacitive

humidity sensor and a thermistor to measure the surrounding air, and

spits out a digital signal on the data pin (no analog input pins needed). Its

fairly simple to use, but requires careful timing to grab data.

Figure 4.9 : Temperature sensor

DHT11 Specifications:

·

Operating Voltage: 3.5V to 5.5V

·

Operating current: 0.3mA (measuring) 60uA

(standby)

·

Output: Serial data

·

Temperature Range: 0°C to 50°C

·

Humidity Range: 20% to 90%

·

Resolution: Temperature and Humidity both are

16-bit

·

Accuracy: ±1°C and ±1%

4.7 LCD Display

LCD

(Liquid Crystal Display) screen is an electronic display module and find a wide

range of applications. A 16x2 LCD display is very basic module and is very

commonly used in various devices and circuits. These modules are preferred over

seven segments and other multi segment LEDs. The reasons being: LCDs are

economical; easily programmable; have no limitation of displaying special &

even custom characters (unlike in seven segments), animations and so on. A 16x2

LCD means it can display 16 characters per line and there are 2 such lines. In

this LCD each character is displayed in 5x7 pixel matrix. This LCD has two

registers, namely, Command and Data.

|

|

|

Figure 4.10: 16*2 LCD Display |

The command register

stores the command instructions given to the LCD. A command is an instruction

given to LCD to do a predefined task like initializing it, clearing its screen,

setting the cursor position, controlling display etc.

Features

of LCD Display

·

5 x 8 dots with cursor

·

Built-in controller (KS 0066 or

Equivalent) + 5V power supply (Also available for + 3V) 1/16 duty cycle

·

B/L to be driven by pin 1, pin 2 or pin

15, pin 16 or A.K (LED) N.V. optional for + 3V power supply.

4.8 Gas Sensor

The utility model can be used for gas leakage monitoring

devices in families and factories, and is suitable for the detection of

liquefied petroleum gas, butane, propane, methane, Hydrogen, smoke,

etc. This is a very easy to use low cost semiconductor Gas sensor Module

with analog and digital output.

Figure 4.11: MQ 2 Gas Sensor

Features:

·

Adopt high quality double panel design, with power

indication and TTL signal output indication.

·

It has DO switch signal (TTL) output and AO analog signal

output.

·

TTL output valid signal is low level. When the output is

low, the signal light is on, and the microcontroller or relay module can be

directly connected.

·

The analog output voltage increases with the concentration,

the higher the voltage.

·

It has better sensitivity to liquefied petroleum gas,

natural gas, urban gas and smoke.

·

MQ-2 MQ2 Smoke Gas LPG Butane Methane Sensor Detector Module

·

With four screw holes, easy to locate.

·

Product size: 32 (L), *20 (W), *22 (H)

·

With long service life and reliable stability.

·

Fast response recovery features

Specifications:

·

Input voltage: DC5V

·

Power dissipation (current): 150mA

·

DO output: TTL, numeric quantities 0 and 1 (0.1 and 5V)

·

AO output: 0.1-0.3V (relatively pollution-free), the highest

concentration of about 4V voltage

·

Special reminder: after the sensor is energized, you need to

preheat 20S or so, the data to be stable, sensor heating is a normal

phenomenon, because the internal heating wire, if hot, it is not normal.

Connection

mode:

·

VCC: power supply positive (5V)

·

GND: power supply negative pole

·

DO:TTL switch signal output

·

AO: analog signal output

·

Functions: This version supporting test procedures

·

Using chips: AT89S52

·

Crystal oscillator: 11.0592MHZ

·

Since this Gas Sensor module is sensitive to smoke it can be

used in for fire detection. MQ2 Gas Sensor is also sensitive to

flammable/combustible gasses like LPG, Propane & Hydrogen.

·

Baud rate: 9600

Internal structure of MQ2 Gas Sensor

The sensor is actually enclosed in two layers of fine

stainless steel mesh called Anti explosion network. It

ensures that heater element inside the sensor will not cause an explosion, as

we are sensing flammable gases.

It also provides protection for the sensor and filters

out suspended particles so that only gaseous elements are able to pass inside

the chamber. The mesh is bound to rest of the body via a copper plated clamping

ring.

This is how the sensor looks like when outer mesh is

removed. The star-shaped structure is formed by the sensing element and six

connecting legs that extend beyond the Bakelite base. Out of six, two leads (H)

are responsible for heating the sensing element and are connected through Nickel-Chromium

coil, well known conductive alloy.

The remaining four leads (A & B)

responsible for output signals are connected using Platinum Wires.

These wires are connected to the body of the sensing element and convey small

changes in the current that passes through the sensing element.

The tubular sensing element is made up of Aluminum

Oxide (AL2O3) based ceramic and has a

coating of Tin Dioxide (SnO2). The Tin

Dioxide is the most important material being sensitive towards combustible

gases. However, the ceramic substrate merely increases heating efficiency and

ensures the sensor area is heated to a working temperature constantly.

So, the Nickel-Chromium coil and Aluminum Oxide based

ceramic forms a Heating System; while Platinum wires and

coating of Tin Dioxide forms a Sensing System.

How does a

gas sensor work?

When tin dioxide (semiconductor particles) is heated in

air at high temperature, oxygen is adsorbed on the surface. In clean air, donor

electrons in tin dioxide are attracted toward oxygen which is adsorbed on the

surface of the sensing material. This prevents electric current flow.

In the presence of reducing gases, the surface density of

adsorbed oxygen decreases as it reacts with the reducing gases. Electrons are

then released into the tin dioxide, allowing current to flow freely through the

sensor.

4.9 Resistor

A resistor is a passive two-terminal electrical component that

implements electrical resistance as a circuit element. Resistors act to reduce

current flow, and, at the sometime, act to lower voltage levels within

circuits. Resistors may have fixed resistances or variable resistances, such as

those founding thermostats, visitors, trimmers, photo resistors, hamsters and

potentiometers. The current through a resistor is in direct proportion to the

voltage across the resistor's terminals. This relationship is represented by

Ohm's law.

Figure 4.12: Resistor

Theory of operation:

The behavior of an ideal resistor is dictated by the relationship

specified by Ohm ‘slaw:

V = I.R

Ohm's law states that the voltage (V) across a resistor is

proportional to the current (I), where the constant of proportionality is the

resistance (R).

Equivalently, Ohm's law can be stated:

I = V/R

This formulation states that the current (I) is proportional

to the voltage (V) and inversely proportional to the resistance (R). This is

directly used in practical computations. For example, if a 300 ohm resistor is

attached across the terminals of a12 volt battery, then a current of12 / 300 =

0.04 amperes flows through that resistor.

4.10

Buzzer

An audio signaling device like a beeper or buzzer may be

electromechanical or piezoelectric or mechanical type. The main function of

this is to convert the signal from audio to sound. Generally, it is powered

through DC voltage and used in timers, alarm devices, printers, alarms,

computers, etc.

Based on the various designs, it can generate different

sounds like alarm, music, bell & siren. The pin configuration of the buzzer

is shown below. It includes two pins namely positive and negative. The positive

terminal of this is represented with the ‘+’ symbol or a longer terminal. This

terminal is powered through 6Volts whereas the negative terminal is represented

with the ‘-‘symbol or short terminal and it is connected to the GND terminal.

Figure

4.13: Buzzer

Specifications

Ø The specifications of the buzzer

include the following.

Ø Color is black

Ø The frequency range is 3,300Hz

Ø Operating Temperature ranges

from – 20° C to +60°C

Ø Operating voltage ranges from 3V

to 24V DC

Ø The sound pressure level is

85dBA or 10cm

Ø The supply current is below 15mA

Working Principle

The working principle of a buzzer

depends on the theory that, once the voltage is given across a piezoelectric material,

then a pressure difference is produced. A piezo type includes piezo crystals

among two conductors.

Once a potential disparity is

given across these crystals, then they thrust one conductor & drag the

additional conductor through their internal property. So this continuous action

will produce a sharp sound signal.

4.11

Arduino IDE

The digital microcontroller

unit named as Arduino Nano can be programmed with the Arduino software IDE.

There is no any requirement for installing other software rather than Arduino.

Firstly, Select "Arduino Nano from the Tools, Board menu (according to the

microcontroller on our board). The IC used named as ATmega328 on the Arduino

Nano comes pre burned with a boot loader that allows us to upload new code to

it without the use of an external hardware programmer.

Communication is using the

original STK500 protocol (reference, C header files). We can also bypass the

boot loader and programs the microcontroller through the ICSP (In Circuit

Serial Programming) header. The ATmega16U2 (or 8U2 in the rev1 and rev2 boards)

firmware source code is available. The ATmega16U2/8U2 is loaded with a DFU boot

loader, which can be activated by:

On Rev1 boards: connecting

the solder jumper on the back of the board (near the map of Italy) and then

resetting the 8U2. On Rev2 or later boards: there is a resistor that pulling

the 8U2/16U2 HWB line to ground, making it easier to put into DFU mode.

The Arduino Nano is one of

the latest digital microcontroller units and has a number of facilities for

communicating with a computer, another Arduino, or other microcontrollers. The

ATmega328 provides UART TTL at (5V) with serial communication, which is

available on digital pins 0 -(RX) for receive the data and pin no.1 (TX) for

transmit the data. An ATmega16U2 on the board channels this serial

communication over USB and appears as a virtual com port to software on the

computer. The '16U2 firmware uses the standard USB COM drivers, and no external

driver is needed. However, on Windows, an .in file is required. The Arduino

software includes a serial monitor which allows simple textual data to be sent

to and from the Arduino board.

The RX and TX LEDs on the

board will flash when data is being transmitted via the USB-to-serial chip and

USB connection to the computer (but not for serial Communication on pins 0 and

1). A Software Serial library allows for serial communication on any of the

Nano's digital pins. The ATmega328 also supports I2C (TWI) and SPI

communication. The Arduino software includes a Wire library to simplify use of

the I2C bus. Arduino programs are written in C or C++ and the program code

written for Arduino is called sketch. The Arduino IDE uses the GNU tool chain

and AVR Lab to compile programs, and for uploading the programs it uses argued.

As the Arduino platform uses Atmel microcontrollers, Atmel's development

environment, AVR Studio or the newer Atmel Studio, may also be used to develop

software for the Arduino.

Figure

4.14: Arduino Software Interface IDE

The Arduino Integrated Development Environment - or Arduino Software

(IDE) - contains a text editor for writing code, a message area, a text

console, a toolbar with buttons for common functions and a series of menus. It

connects to the Arduino and Genuino hardware to upload programs and communicate

with them.

Writing Sketches

Programs written using Arduino Software (IDE) are called sketches. These

sketches are written in the text editor and are saved with the file extension.

ino. The editor has features for cutting/pasting and for searching/replacing

text. The message area gives feedback while saving and exporting and also

displays errors. The console displays text output by the Arduino Software

(IDE), including complete error messages and other information. The bottom

right hand corner of the window displays the configured board and serial port.

The toolbar buttons allow you to verify and upload programs, create, open, and

save sketches, and open the serial monitor.

4.12 Proteus Software

The Proteus Design Suite is a proprietary

software tool suite used primarily for electronic design automation. The

software is used mainly by electronics design engineers and technicians to

create schematics and electronics prints for manufacturing printed circuit

boards.

The first version of what is now the Proteus

Design Suite was called PC-B and was written by the company chairman, John

Jameson, for DOS in 1988. Schematic Capture support followed in 1990 with a

port to the Windows environment shortly thereafter. Mixed mode SPICE Simulation

was first integrated into Proteus in 1996 and microcontroller simulation then

arrived in Proteus in 1998. Shape based auto routing was added in 2002 and 2006

saw another major product update with 3D Board Visualization. More recently, a

dedicated IDE for simulation was added in 2011 and MCAD import/export was

included in 2015. Support for high speed design was added in 2017. Feature led

product releases are typically biannual, while maintenance-based service packs

are released as required.

Figure

4.15: Proteus Software Interface

4.13 Microcontroller Code

Install this code to https://io.adafruit.com/

#include

<Wire.h>

#include

<LiquidCrystal_I2C.h>

LiquidCrystal_I2C

lcd(0x27 , 16,2);

#include

<SimpleDHT.h> //

Data ---> D3 VCC ---> 3V3 GND ---> GND

#include

<ESP8266WiFi.h>

#include

"Adafruit_MQTT.h"

#include

"Adafruit_MQTT_Client.h"

//

WiFi parameters

#define

WLAN_SSID "abcde"

#define

WLAN_PASS "123456789"

//

Adafruit IO

#define

AIO_SERVER

"io.adafruit.com"

#define

AIO_SERVERPORT 1883

#define

AIO_USERNAME "samiul"

#define

AIO_KEY

"aio_zzrG72lmNmNEwE4c9Kwd8IgLmy2b"

WiFiClient

client;

//

Setup the MQTT client class by passing in the WiFi client and MQTT server and

login details.

Adafruit_MQTT_Client

mqtt(&client, AIO_SERVER, AIO_SERVERPORT, AIO_USERNAME, AIO_KEY);

Adafruit_MQTT_Publish

Temperature1 = Adafruit_MQTT_Publish(&mqtt, AIO_USERNAME

"/feeds/temperature");

Adafruit_MQTT_Publish

Humidity1 = Adafruit_MQTT_Publish(&mqtt, AIO_USERNAME

"/feeds/humidity");

Adafruit_MQTT_Publish

smoke11 = Adafruit_MQTT_Publish(&mqtt, AIO_USERNAME

"/feeds/smoke");

int

pinDHT11 = D5;

int

smoke = D6;

int

smoke1;

SimpleDHT11

dht11(pinDHT11);

byte

hum = 0; //Stores humidity value

byte

temp = 0; //Stores temperature value

void

setup() {

Serial.begin(115200);

pinMode(D6,INPUT);

lcd.begin(16,2);

lcd.init();

lcd.backlight();

Serial.println(F("Adafruit IO

Example"));

// Connect to WiFi access point.

Serial.println(); Serial.println();

delay(10);

Serial.print(F("Connecting to "));

Serial.println(WLAN_SSID);

WiFi.begin(WLAN_SSID, WLAN_PASS);

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(F("."));

}

Serial.println();

Serial.println(F("WiFi

connected"));

Serial.println(F("IP address: "));

Serial.println(WiFi.localIP());

// connect to adafruit io

connect();

}

//

connect to adafruit io via MQTT

void

connect() {

Serial.print(F("Connecting to Adafruit

IO... "));

int8_t ret;

while ((ret = mqtt.connect()) != 0) {

switch (ret) {

case 1: Serial.println(F("Wrong

protocol")); break;

case 2: Serial.println(F("ID

rejected")); break;

case 3: Serial.println(F("Server

unavail")); break;

case 4: Serial.println(F("Bad

user/pass")); break;

case 5: Serial.println(F("Not

authed")); break;

case 6: Serial.println(F("Failed to

subscribe")); break;

default:

Serial.println(F("Connection failed")); break;

}

if(ret >= 0)

mqtt.disconnect();

Serial.println(F("Retrying

connection..."));

delay(10000);

}

Serial.println(F("Adafruit IO

Connected!"));

}

void

loop() {

// ping adafruit io a few times to make sure

we remain connected

if(! mqtt.ping(3)) {

// reconnect to adafruit io

if(! mqtt.connected())

connect();

}

smoke1

= digitalRead(D6);

if(smoke1 == LOW){

lcd.clear();

lcd.setCursor(0, 0);

lcd.print(" Smoke Detected ");

delay(2000);

}

if(smoke1 == HIGH){

}

dht11.read(&temp, &hum, NULL);

Serial.print((int)temp); Serial.print("

*C, ");

Serial.print((int)hum); Serial.println("

H");

lcd.clear();

lcd.setCursor(0, 0);

lcd.print("

Temp Humidity");

lcd.setCursor(2, 1);

lcd.print(temp);

lcd.setCursor(10, 1);

lcd.print(hum);

if ( Temperature1.publish(temp)) { //Publish to Adafruit

Serial.println(F("ok"));

}

delay(2000);

if ( Humidity1.publish(hum)) { //Publish to Adafruit

Serial.println(F("ok"));

}

delay(2000);

if ( smoke11.publish(smoke1)) { //Publish to Adafruit

Serial.println(F("ok"));

}

delay(2000);

}

Conclusions

5.1 Advantage

There are certainly many advantages of our project

and some of the major ones have been given below:

• The system

shows the present weather condition on LCD display.

• Saves time

and physical work.

• This

project is easy to use.

• This

project can be measured Temperature, Humidity, detect gas & Storage This

Data Via Internet.

5.2 Disadvantages

This project has some disadvantages. These are –

Ø Internet connectivity is a must to drive this project smoothly.

Ø Notification may delay for weak internet connection.

5.3 Application

The project is very

compact and uses a few components only. It can be implemented for several

applications; the project has a major application in the

• Power

grid.

• Factories.

• Mills and

Industrial areas.

• Weather

Monitoring Station.

• BTS Room

• Green

House

5.4 Future Scope of Work

We have few future scopes of work available to us for this

project. Some of these are listed below:

- In

Future Development To make it more efficient can be added in this project

more sensor & controlling system.

- In

future we are thinking to add alarming system for alert from unwanted

weather condition.

5.5 Conclusion

This

system is for measuring the parameters values and to detect the temperature,

humidity, Smoke Detector of Weather. This project Design and Implementation of

Weather Monitoring System & data storage used for controlling the devices

as well as monitoring the environmental parameters. Embedded controlled sensor

networks have proven themselves to be a reliable solution in providing remote

control and sensing for environmental monitoring systems. The sensors have been

integrated with the system to monitor and compute the level of existence of

temperature, humidity, & Smoke with IOT technologies. The sensors can

upload the data in web using serial Communication via internet.

REFERENCES

[1] Sebastian

van Delden and Andrew Whigham 2013 A Bluetooth-based Architecture for Android

Communication with an Articulated Robot IEEE

[2] SatishPalaniappan,

Naveen Hariharan, Naren T Kesh and Angel Deborah S 2015 A Study – Home

Automation Systems International Journal of Computer Applications 116(11) 0975

–8887

[3] ShiyuZheng

and Hong Xu 2014 The remote monitoring system basedon RaspberryPi Microcomputer

and Its Applications 19:105-107

[4] T.

Maria Jenifer, T. S. Vasumathi Priyadharshini, Raja Lavanya and S. Raj Pandian

2013 Mobile Robot Temperature Monitoring System Controlled by Android

Application via Bluetooth International Journal on Advanced Computer Theory and

Engineering

[5] Mark

W. Spong and Masayuki Fujita, AbdulIshaq T.K and Mohammed Irfan K.A 2016

Gesture Controlled robotic arm using wireless networks International Journal of

Core Engineering & Management 3(1)

[6] Arasteh,

H., Hosseinnezhad, V., Loia, V., Tommasetti, A., Troisi, O., Shafie-Khah, M.,

and Siano, P. 2016 Iot-based smartcities: a survey IEEE 16th International

Conference Environment and Electrical Engineering (EEEIC) 1-6.

[7] Augusto,

J. C., and McCullagh, P. J. 2007. Ambient intelligence: Concepts and

applications. Computer.Sci. Inf. Syst. 4(1) 1-27.

[8] Baggio,

A. 2005.Wireless sensor networksin precision agriculture Real World Wireless

Sensor Networks Stockholm Sweden Vol. 20.

[9] Bahrepour,

M., Meratnia, N., Poel, M., Taghikhaki, Z., and Havinga, P. J. 2010 Distributed

Event detection inwireless sensor networks for disaster management

International conference on intelligent networking and collaborative systems

507-512/ IEEE

[10] Srinivas

K, Kumar JT and Merugu S 2019 GEVD based on multichannel wiener filter for

removal of EEG artifacts International Journal of Innovative Technology and

Exploring Engineering 8(10) 2417-2421 10.35940/ijitee.H6755.0881019

[11] Jhansi

Rani G, Raghava Kumari D, Anitha M and Sarita B 2020 Analysis of raspberry pi

based ATM theft monitoring and security system International Journal of

Psychosocial Rehabilitation 24(8) 15376-15383 10.37200/IJPR/V24I8/PR281514

[12] Anitha

M., Jhansi Rani G., Raghava Kumara D and Anuradha P. 2020 Implementation of

arthemetic logic unit using quaternary signed digit number system International

Journal of Psychosocial Rehabilitation 24(8) 15363-15375

10.37200/IJPR/V24I8/PR281513

[13] Raghava

Kumari D, Anitha M, Jhansi Rani G and Ramesh Babu D 2020 Road traffic control

by using Li-Fi technology between vehicle to vehicle communications

International Journal of Psychosocial Rehabilitation 24(8) 15393-15397

10.37200/IJPR/V24I8/PR281516

[14] Swathi

N, Padmaja Ch and Navya Jyothi G 2020 Audio assistive for blind people to

identify the cloth patterns and colors Journal of Critical Reviews 7(17)

154-158 10.31838/jcr.07.17.23

[15] Mahender

K, Ramesh KS and Kumar TA 2017 An efficient OFDM system with reduced paper for

combating multipath fading Journal of Advanced Research in Dynamical and

Control Systems 9(Special issue 14) 1939-1948

Comments

Post a Comment